RF Micro Devices Finds Success in Continuous Improvement

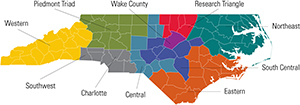

Semiconductors are a competitive field in today’s high-tech culture, but Greensboro-based manufacturer RF Micro Devices (RFMD), in its relentless quest for better product yields and process improvements, leverages Six Sigma to remain at the front of the pack.

“Constantly improving and streamlining is a concept that’s embedded in our business,” says Michael Ferrara, RFMD program manager. “Within our Six Sigma program, we’re constantly looking at metrics and completion rates, making sure there’s a good success rate with our projects.”

Six Sigma, developed nearly three decades ago by electronics company Motorola, is a data driven approach for process improvement. Participants follow a set of techniques and tools that identify and remove errors and minimize variability in manufacturing and business processes. Six Sigma experts carry titles that reflect their skill level, such as “black belt” and “green belt.”

Keeping it Fresh

Ferrara, a black belt trained and certified though NC State, was introduced to Six Sigma by RFMD Director of Quality Craig Callahan.

“Craig is also a long time black belt, has been cultivating the Six Sigma culture here at RFMD over the past 10 years,” Ferrara says. “We’d found from benchmarking that programs in any industry were at risk of going through a program lifecycle of everyone being energized, then reaching peak interest rate, then interest fading. Here at RFMD we wanted to find ways to keep the Six Sigma program fresh and energized in order to de-couple from these industry trends and stay at peak interest rates.”

With help from NC State Industry Expansion Solutions (IES), RFMD is steadily growing the number of employees who have achieved both green and black belts. During training, Six Sigma participants are given projects that they continue working on in the “real world” outside the classroom.

“This way, they’re focusing on the methodology of Six Sigma instead of learning a new skill set,” Ferrara says. “They’re applying their training in an area of work they’re already assigned to, and responsible for.”

“RF Micro Devices has focused attention on developing a Six Sigma program for the company that will continually create improvements to the company’s processes and result in significant return on investment,” says IES Regional Manager Ken Hoover. Results from the current Green Belts’ projects have created an energy within the company, and a wave of requests to participate in future training. “This demonstrates to me the success and support essential for future program growth,” says Hoover.

The Move Forward

RFMD realized multi-million dollar cost savings in 2013, and Ferrara says Six Sigma application in a pair of company projects—development of better processes for inventory control levels and final product test efficiency—played a strong role in achieving it.

Now, they are looking at the big picture for further inspiration.

“We’re looking to see how the methodology is being used by other industries like healthcare and education,” Ferrara says. “Seeing some of the projects they’re working on, and how they’re applying Six Sigma, gave us some ideas, such as a re-balance of project mix with increased emphasis on Lean. We had a light bulb moment there.”

DOWNLOAD NOW » Click here to download a PDF of this Client Success Story.