- This event has passed.

Standard Work for Lean Leaders: Going to Gemba with Purpose

February 8, 2024 @ 10:00 am - 11:00 am

Free

Who Should Attend

Managers and front-line leaders who want to build a continuous improvement culture that is practiced daily, not event-based.

Taiichi Ohno, one of the founders of the Toyota Production System, once said, “The greatest waste of all is the waste that we don’t see.” It is impossible to lead in a continuously improving environment without being able to identify waste that keeps our operation or service from performing at a high level.

Participants will leave the webinar with an understanding of how to better assess the condition of their operation, especially regarding whether material, people, and information are flowing as planned vs. in abnormal conditions. They will also better understand how to challenge their staff (especially front-line leaders) to identify waste that is keeping their operation from performing more effectively.

Key Takeaways:

- Ability to understand the purpose of a leader in a Lean environment

- Learn the importance of performing confirmation checks in your work environment to confirm the status of your material, information and people flow and identify opportunities to improve

- How to teach and coach others in your organization to see waste

Presenter

Bill Iacovelli

Bill Iacovelli

Extension Specialist, NC State University Industry Expansion Solutions

Email: bill_iacovelli@ncsu.edu | Phone: 704.750.0804

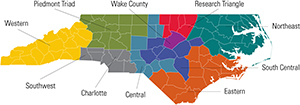

Based out of the IES Concord office, Bill works state-wide to help manufacturers, businesses, healthcare systems and government agencies improve through Lean and Six Sigma thinking and methodology. Bill assists organizations in developing systematic, long-term Lean implementation and leadership programs. He also trains and develops Lean Six Sigma Green Belts.

In 16 years, relative to his project work with them, Bill’s clients (through a third-party survey) have reported over $74M to NIST in economic impact and over 500 jobs retained or created. Before joining IES, Bill worked for Eastman Kodak Company in technical and supervisory roles in manufacturing, research and development. He was also a Lean implementer, trainer and coach in manufacturing, utilizing leadership coaching, Kaizen and other Lean tools.

Bill holds a B.S. in industrial engineering and operations research from Virginia Polytechnic Institute and State University (Virginia Tech) and an MBA (concentrating on manufacturing management and quality management) from the Rochester Institute of Technology (RIT). He is a certified Lean Six Sigma Black Belt. Bill serves on the Association for Manufacturing Excellence (AME) southeastern region board, Jay M. Robinson High School’s engineering and automation academy’s advisory board and is a member of NC State’s academy of outstanding faculty engaged in extension and engagement.