Manufacturing Network Fosters Local Supply Chains

Sanford-based company Mertek designs and makes all kinds of machines. Its clients are other manufacturers around the world, who in turn use those machines to produce products ranging from cosmetics to vodka, intake manifolds to sprinkler systems. Mertek’s machines are custom-designed not only to produce items like corks and cosmetic cases, but also to test items for defects, or to handle parts as they move along production lines. In most cases, Mertek can design and build exactly what a client needs to most quickly and efficiently produce its goods.

Though the Pedleys’ deepest roots run to farming, the family has carved out a niche for itself in advanced manufacturing. Designer Kirk Pedley, Manufacturing Manager Kevin Pedley and President Jerry Pedley—who together make up one-half of the design team— have seen the manufacturing landscape change dramatically in recent years. The company has adapted by embracing new technologies like robotics and 3D printing to meet the demands of their sophisticated customers. As the company’s capabilities continue to expand, Jerry Pedley is always looking for new ways to communicate them to both existing and potential customers.

Bringing the Supply Chain Home

Two of the machines Mertek is currently building are destined for facilities in India; another two will be shipped to Italy. But in recent years, a number of finished products have been bound for local manufacturers, thanks in part to Mertek’s membership in the Manufacturing Makes It Real Network.

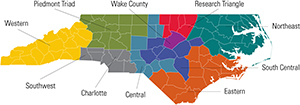

The Network is a membership-based group of small- and medium-sized manufacturers across the state, administered by North Carolina State University Industry Expansion Solutions (IES). The Network regularly convenes to share knowledge, localize their supply chains, promote their businesses and network with one another. A long-term client of IES, Mertek joined the Network in 2012, after Jerry Pedley dipped his toes in the water by attending an event as a guest. Now, Mertek is seeing the perks of membership; the company recently reported increased sales leading to job creation and growth within the company.

“We’ve been to around a dozen events, and have taken advantage of the opportunity to give a two-minute presentation about our company,” says Jerry Pedley. “Half the time, someone will come up afterward and ask us if we can make a machine for them.”

Fringe Benefits

According to IES Regional Manager Kami Baggett, the benefits derived from Mertek’s Network membership flow both ways; Jerry Pedley recently accepted an appointment to the IES Advisory Board, where he assists IES in leading NC manufacturers to solid resources that provide them with solutions to their needs.

“We have gained an absolutely wonderful manufacturing advocate in Jerry and his company,” says Baggett. “He goes above and beyond to support and celebrate manufacturing in our state.”

Mertek has taken part in national Manufacturing Day, or MFG Day, since 2012, which is organized in North Carolina by IES. On MFG Day for the past three years, Mertek has opened its doors to students from public schools so that the next generation can see highly skilled technicians and engineers at work.

Manufacturing Manager Kevin Pedley believes that fostering an interest in advanced manufacturing will help the company find the talent it needs to continue thriving well into the future.

“To keep manufacturing alive, that’s what has to happen,” he says. “It’s not our parents’ jobs anymore. These are high-tech jobs— building machines and keeping them running.”

DOWNLOAD NOW » Click here to download a PDF of this Client Success Story.