ArcelorMittal Achieves OHSAS 18001 Certification, Increases

Safety Focus

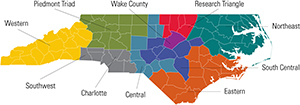

ArcelorMittal is the world’s leading steel and mining company. It operates in 60 countries and employs 245,000 people worldwide. Its Newton, NC plant produces steel products like axles and rolled pipe for companies like Meritor, Bristol Metals and Komatsu, cutting steel ranging from 1/4-inch up to 4 inches thick. The process involves a bevy of potential hazards.

“Metal work is dangerous,” says David Hedrick, the engineer who headed the OHSAS 18001 certification project. “Globally last year, ArcelorMittal had 29 fatalities, and the company has already experienced five this year. We have to look at those hazards that we have and try to control them.”

In 2011 corporate leadership issued a company-wide directive: seek OHSAS 18001 certification and bring down the number of workplace accidents. Though the Newton carbon steel plant had never had the elevated safety issue numbers of other ArcelorMittal facilities, both Hedrick and Plant Manager Scott Gilfillan understood that greater attention to safety protocols could positively affect both their workers and their bottom line.

About OHSAS 18001

OHSAS 18001 is an international occupational health and safety management system specification intended to help organizations control occupational health and safety risks.

The system is applicable to any organization wishing to:

• Establish an OH&S management system to eliminate or minimize H&S hazards

• Implement training, inspections and other activities to meet their OH&S policy

• Demonstrate conformance to OHSAS 18001 and OSHA regulations

• Implement, maintain and continually improve an OH&S management system

• Make a self-declaration of conformance with OHSAS specifications, or

• Acquire certification to OHSAS by an accredited organization

To assist in the certification training, ArcelorMittal sought the help of the NC State University Industry Expansion Solutions (IES). Improvement Specialist Charlie Parrish worked directly with Hedrick and Gilfillan.

“Charlie made four to five visits up here and went through the systems we had written out,” says Hedrick. “He also did a mock audit for us. In the end, we brought in the auditors for the 18001 certification and made it through with no action items.”

Taking the Gray Out of Safety

As a result of OHSAS 18001 implementation, the plant realized $30,000 in direct economic impact. This stemmed from additional business, as well as a reduction in labor hours for project planning.

Hedrick sees real value in the process.

“When we get ready to do a job, we now take time beforehand to look at the risk,” he says. “It saves us time from not running into obstacles that we might not have planned for in the past.”

“The huge benefit we have is a culture of safety. The guys that work here have taken ownership of the system,” adds Gilfillan. “It’s a lot nicer working in an environment where you know this is how we do things, and this is not how we do things, instead of a lot of gray area. It’s a lot better place to work.”

Gilfillan is proud of his company’s commitment to safety. “Lots of companies say safety is number one,” he says. “ArcelorMittal means it.”

DOWNLOAD NOW » Click here to download a PDF of this Client Success Story.