It is exciting when a small manufacturer grows. Developing as a business means an increasingly diverse market, more jobs created and the ability to contribute more to the community. But expanding doesn’t come without challenges. When your customer base grows, your processing output and facility space must advance along with it.

Located in Murphy, North Carolina, Aegis Power Systems, Inc. is a leading supplier of AC-DC and DC-DC power supplies for custom and special applications. Aegis has been designing and building highly reliable custom power supplies since 1995. The organization offers a complete line of switch mode power supplies and power converters for various markets including defense, industrial, aircraft, electric vehicle, and telecom. Aegis Power Systems maintains an agile workforce to support low-volume production – a valuable trait for defense businesses in the product research and development stage.

“Aegis,” a Greek word from Homer’s epics, the Iliad and the Odyssey, Aegis was represented as an unyielding leather cloak or breastplate used to protect Zeus in battle. Aegis Power Systems has lived up to its symbolic name; its quality products and customer service values have won numerous awards including Northrop Grumman’s “Suppliers Excellence Award“, “Reliability in Quality” award from the US Navy and the “Outstanding Support Award” from Harris Corporation (now L3 Harris).

Aegis Power Systems CEO, Arlissa Vaughn, oversees the various departments within the organization and a glaring problem she observed was the lack of space in their facility. “A challenge Aegis Power Systems realized was that the limited facility space was stunting the potential of our engineering team,” Vaughn stated. Due to the restricted workspace, Aegis Power Systems’ prototyping and production spaces were overlapping, disrupting the workflows.

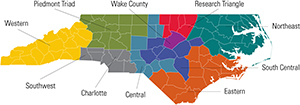

Looking to expand its facility, Aegis Power Systems reached out to NC State University Industry Expansion Solutions (IES). IES regional manager Chris McGraw connected Aegis with industrial design resources to create a blueprint for optimizing their space and expanding their existing facilities. “We not only wanted to build space for practical reasons but we also wanted to do it to conserve funds, maximize resources and get high-quality products done as efficiently as we could,” said Vaughn.

The power systems manufacturer was interested in new business opportunities in the defense market when they first worked with NC State University Industry Expansion Solutions through the North Carolina Defense Industry Diversification Initiative (NCDIDI), a program that helped Aegis maximize its growth potential and cybersecurity resiliency.

When Vaughn needed help with space and expansion planning, she reached out to IES because they were familiar faces and used to working with small businesses. Vaughn claimed, “As a small organization, we’re resource-sensitive; IES was aware of that fact. If you do a simple Google search for an architecture or engineering firm that does manufacturer studies, almost all of them will charge you an arm and a leg. Never during the process of working with IES did they propose something we couldn’t afford. They customized a plan for us personally.”

IES helped Aegis complete a SWOT (strengths, weaknesses, opportunities, and threats) analysis of the areas they needed to refine to see the maximum output. “We are in the habit of seeing if we can come up with a solution ourselves before we look for any external assistance but we were all glad about bringing in IES to help. IES provided thorough evaluation and new approaches that saved us from making costly mistakes,” Vaughn confessed.

In October 2022, Aegis Power Systems held the official grand opening ceremony of the expanded facility. “The engineers are thrilled that they have so much more space and the production and engineering departments are no longer interrupting each other,” Vaughn stated. “It saved the workflow and reduced the noise level.”

Increased room for research and development isn’t the only exciting change. “Before, it was hard for us to have a company-wide meeting because we didn’t have the space. We had to stand around in the production area or rent space elsewhere,” Vaughn said. With the new upgrade to their facility, Aegis employees have the social space needed for meetings, lunch and other employee engagement events. “We got this new breakroom and it’s been awesome. Our previous breakroom is funny to look at now because we could only fit four people at a time during Covid-restrictions. We can see how the new area promotes a more social and collaborative environment,” Vaughn continued. “We’re extremely grateful that this worked out the way it did.”

As a result of working with IES and other partner organizations, Aegis Power Systems invested $6,000 in new products or processes, $120,000 in plant and equipment and $5,000 in workforce practices and employee skills. The organization also created eight new jobs and avoided $70,000 in unnecessary investment.