Founded in 1899, VF Corporation is the parent company to some of the most iconic brands in the world. It is one of the world’s largest apparel, footwear and accessories companies that includes the likes of Vans®, The North Face®, Timberland® and Dickies®.

In all, the company owns 20+ brands, employs 50,000+ associates and operates in 150+ countries worldwide. Sustainability and responsibility are at VF’s core. Manufacturing more than 500 million units of product every year, they consider how, where and by whom those products are made, as well as the associated environmental, safety and social impacts.

Global Business Platforms, Central Resources and Strategic Investments Allow VF to Thrive

Additionally, the purpose-led, performance-driven company aspires to connect all their brands through global business platforms, central resources and strategic investments that allow them to thrive.

Kyle Cutsail, VF’s Vice President of Global Health and Safety, said, “VF is a people first organization. Our ambition is to allow VF associates to live their most fulfilling lives and believe it is our obligation to lead the way by upholding safety in every one of our facilities.”

So, in 2018, VF’s supply chain leadership team, in partnership with VF’s health and safety and factory compliance team, began the process of aligning and transforming their health and safety program. The goal? To build on the ongoing safety efforts and expand to a centralized, proactive and consistent VF Governed Safety Program across the world.

Cutsail said, “Our goal was to build program strategies around real-time data and ensure clarity and alignment of all VF safety requirements and programs. This will ultimately allow us to embed a culture of safety across the company.”

The VF Governed Safety Program

The expert teams got to work and laid out the new VF Governed Safety Program that consisted of culture enhancement, standards, implementation tools, KPI’s and verification audits. Every part of the safety program was to be based on a VF standard, which also dictated the audit protocol as the final verification of a successful program at a site. In addition, the teams wanted to develop a VF safety program certification course that could be used to align and develop everyone’s technical safety skills.

“Ensuring consistency of knowledge for all of our safety professionals is critical to the success of a program of this size. We believed VF’s internal facility safety managers, factory compliance auditors and sustainable operations teams could benefit from receiving the same educational/training opportunity across the globe,” said Cutsail.

The next challenge? Finding a trusted advisor who could develop the course.

Consistency in Training is Key Across the Globe

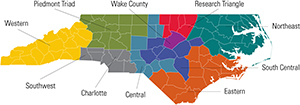

In 2019, Cutsail began his search for that trusted advisor and landed on NC State’s Industry Expansion Solutions (IES). An extension of the College of Engineering, IES is also home to the Southeastern OSHA Training Institute Education Center (SE OTIEC).

Over a period of six months, IES developed a customized, OSHA 30 Hour General Industry trainer course for VF that established consistent, baseline knowledge that could be transferred across the world, as well as issue certificates of completion to VF trainers, no matter where their geographic location may be. As part of their work, IES developed a tailored training agenda and outline of safety topics; trainer lesson plans that included slides and training activities for each topic; an instructor guide and a participant manual.

In addition, IES trained the inaugural group of VF trainers for five days in Greensboro, North Carolina. Cutsail sat in on the class. “IES got it right. They spent a good amount of

time understanding our business, the history of our safety journey, how we functioned and our aspiration for the future of the VF Governed Safety Program. This was evident in the course they delivered to our trainers,” said Cutsail.

The course and ancillary certification of completion are designed to ensure that all VF employees and outsource partners, who have safety responsibility for the company, have the opportunity to learn from the same knowledge base. “Consistency in training ensures everyone understands the company’s safety policies and their role within the company. And, thanks to the professional work from IES, every employee and outsource partner sees the same material, hears the same messages and is tested in the same way,” said Cutsail.

DOWNLOAD NOW » Click here to download a PDF of this Client Success Story.